日志

Aluminum Foil Features & Advantages

||

It bears the name, but it is not paper! Moreover, it is more accurate to speak of aluminum foil. Arrived in the late 1920s in the United States, then in the mid-1930s in Europe, aluminum foil quickly seduced all homes with the multiplicity of its uses, its thermal performance and its hygienic qualities. It is obviously used in the kitchen to pack, preserve, protect and cook. But that's not all! It can also be used for decoration, as a heat reflector, as a scarecrow, in construction, transportation, household appliances, electrical and electronic equipment, machinery, printing and for medical uses.

From bauxite to aluminum foil

After oxygen and silicon, aluminum is the third most abundant element in the Earth's crust, resulting from the refining of bauxite. From this ore, we first obtain alumina, pure aluminum oxide. Then, by passing an electric current through the alumina, aluminum metal is produced. This is called electrolyte reduction.

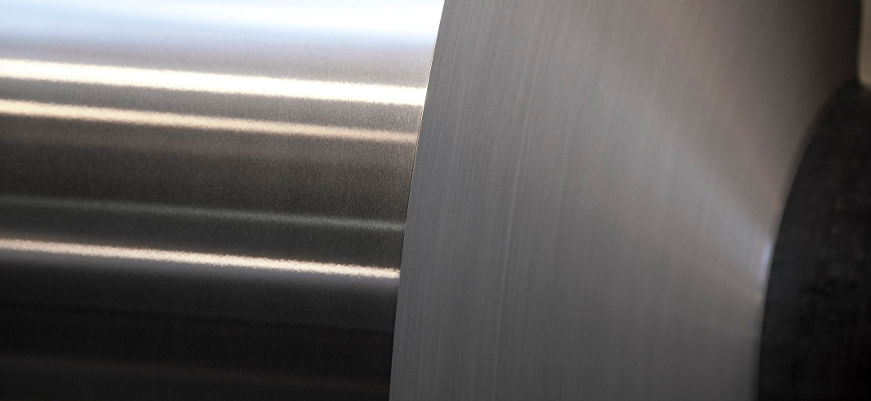

To make heavy duty aluminum foil, plates are passed several times to the rolling mill.

There are two methods to do this:

The first consists of two successive rollings. First that of heated ingots, which makes it possible to obtain coils of 2 to 4 mm thick. Then a second cold rolling which makes it possible to obtain the final aluminum sheets whose thickness required by the ISO standard is between 0.006 and 0.2 mm. Thicker, this will be an aluminum plate or sheet metal.

The second method makes it possible to transform the molten metal directly into a thick strip, itself laminated into a coil, from which the aluminium foil is rolled. This avoids the ingot stage.

The second method makes it possible to transform the molten metal directly into a thick strip, itself laminated into a coil, from which the aluminium foil is rolled. This avoids the ingot stage.

And have you ever wondered where this difference between the two sides of aluminum foil, one shiny and the other matte, came from? Here is the explanation: to avoid damaging the thinnest leaves, they are passed by two between the rollers. As a result, the side that faced the roller comes out shiny and the one that was facing the other aluminum foil is satin.

Once the two sheets are separated, the large rolls of 6061 aluminum plate are cut according to their final use: insulating sheets, household aluminum, heat exchanger, packaging, container, sealing...

Aluminum foil and all its virtues

- Against waste: barrier to light, gas and moisture, aluminum foil perfectly preserves the aromas and prolongs the life of sensitive products.

- Practical and ideal for packaging: lightweight, strong and deformable, aluminum allows you to pack all forms of products.

- Healthy and hygienic: 100% sterile, aluminum foil prevents the development of bacteria.

- Resistant to the highest and lowest temperatures: excellent thermal conductor, aluminum foil allows freezing as well as baking or grilling, without melting, deforming or cracking.

- Decorative: aluminum foil can be used in all printing and embossing techniques, for any advertising, decorative or artistic use.

Recyclable and reusable: aluminum can be recycled endlessly, without ever losing its qualities.